Our Initiatives: Corporate Operations

Manufacturing and Distribution

MANUFACTURING FACILITIES

Maidstone Coffee

In 2012, both our coffee roasting plants, in Ancaster, ON, and Rochester, NY, continued to make solid gains in diverting packaging waste from landfill. At Maidstone Ancaster, 100% of our jute bags holding green coffee are being recycled, for uses that include stuffing for furniture.

The coffee chaff, or outer skin of the coffee bean, has started to be recycled as compost at local farms and as a fuel source for bioenergy production.

Our facilities also recycle 100% of their cardboard and plastic wrap. A new initiative is underway to recycle the metalized plastic film used in our restaurant packaged coffee. Testing for this project will begin in 2013.

Fruition Fruits & Fills

Fruition Fruits & Fills (Fruition) is our fondant and fills manufacturing facility. It produces our fondants, fills, icings, and ready-to-use glaze that are used on a number of our

baked good products, and the syrups used to make our Fruit Smoothies.

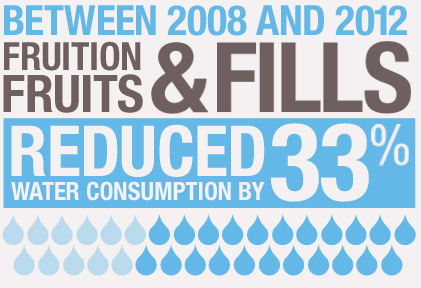

The production of icing and fruit-based filling and glaze has typically been water intensive. Therefore, in past years, Fruition has focused on reducing the amount of water used

in its manufacturing process. Between 2008 and 2012, we have reduced our water consumption by 33%.

Our focus in 2012 was on reducing waste and improving diversion rates. This was done through efforts to educate employees on the importance of reducing waste in team meetings

and by displaying photographs in common areas showing where and how the right type of waste should be disposed of to maximize success. Through these efforts and previous years’

activities, the current diversion rate for Fruition Fruits & Fills is 84%.

Distribution and Warehousing

As a vertically integrated company, our network of distribution centres (DCs) across Canada is a significant source of our energy consumption and, due to our distribution fleet, the main

source of our corporate carbon footprint. Our DCs house and transport a variety of ambient, refrigerated and frozen products across the country to the majority of our restaurants.

Energy

Our DCs are continuously piloting and implementing projects aimed at increasing efficiency of our operations and reducing environmental impact. A few of our 2012 projects

included:

- Guelph: The Guelph distribution fleet was completing 135 backhaul loads per month, bringing goods from suppliers back to the centres. This is the equivalent

of eliminating 68 full truckloads from the highway.

- Kingston: We began a long combination vehicle (LCV) program increasing the length of trailers we are permitted to transport. The LCV program allowed us to reduce

176,400 kilometers and save 75,000 liters of fuel in our fleet.

- We worked with our employees to implement behavioural change initiatives to power off lights, televisions, computers, and other electrical equipment when not in use,

and to keep overhead doors closed when not in use.

Waste

In 2012, we placed a greater focus on recycling and waste diversion programs at our DCs. We expanded our recycling and waste diversion programs and established a baseline of

waste data. We are currently diverting 70% of our waste from landfill.

With the baseline diversion rate established, we will be working towards a 10% increase in waste diversion at all of our facilities. We are also working on increasing the

amount of recycling opportunities that we can offer to our restaurants. In 2012, our Langley facility continued to backhaul plastic muffin trays and fondant pails. In 2013,

we are aiming to recycle approximately 3,200 kilograms of plastic pails from our restaurants backhauled to our DCs.

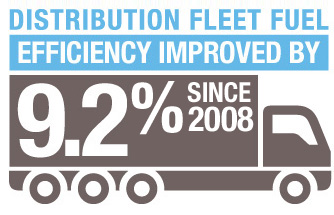

Transportation Efficiency

In 2012, our Tim Hortons commercial truck fleets based in Ontario, BC, Alberta and Nova Scotia attained a fuel efficiency of 2.4 kilometers per litre (KPL).

We aim to improve our idling rate in 2013. A tool that will greatly assist with the reduction of fleet idling is our new Electronic On Board Recorder (EOBR), which we

are currently installing in all of our fleet trucks and buses. The EOBR will allow us to track the many facets of our drivers’ daily truck operations and encourage them

to adopt the right behaviours.

We intend to continue to improve our fleet fuel efficiency through the specifications we currently employ on our trucks (energy efficient engine and cab heaters; aerodynamic

roof, chassis, cab and front bumper farings; etc.) and the ongoing replacement of pre-2010 trucks with new, 2013 lower-emission trucks.

Tim Hortons recognized that the traditional method of refueling at a cardlock had a negative impact on the environment because each truck would burn more fuel as it

travelled the extra 2-3 kms to a fueling station. [Tim Hortons requested that 4Refuel quantify the impact on greenhouse gas emissions by reducing their drive time to

pick up fuel.] In 2012, we estimate that Tim Hortons eliminated over 112,000 kms in driving and reduced GHG emissions by 131,710 kgs by utilizing an onsite refueling

program versus a cardlock system.

4Refuel

To further its efforts in reducing fuel consumption, vehicle wear and tear, and fleet safety, Tim Hortons recently worked with the Private Motor Truck Council to update and

implement a driver training program originally produced by Natural Resources Canada. The customized version of ‘Smart Driver for Highway Trucking’ teaches Tim Horton’s

drivers safe driving and fuel conservation techniques, and reinforces the company’s own operations policy.

Private Motor Truck Council

Compared to the environmental impact of our restaurant operations and distribution fleet, the environmental footprint of our corporate offices is minor. However, in an effort to

improve the environmental footprint in all areas of our business, our Corporate Facilities Team has continually focused on making our corporate buildings more energy and water

efficient.

Our head office campus in Oakville, ON, is made up of three buildings that vary in age from five years to 40 years old, and houses approximately 800 employees. Our two main office

buildings are actually repurposed distribution facilities used by our Company a number of years ago. The original building on our Oakville campus was a Tim Hortons restaurant

that has also been repurposed into office space.

Energy and Water

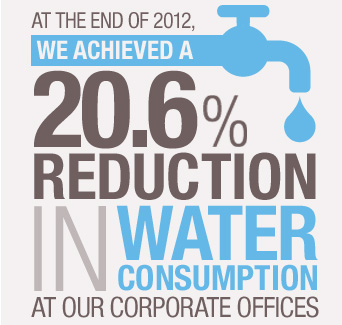

In 2012, we set a goal to reduce our energy and water use at corporate offices by 10% by the end of 2014, as compared to 2011 consumption. At the end of 2012, we have met our

goal for water usage, achieving a 20.6% reduction in water consumption. Our energy consumption decreased by 8.7% at

corporate offices in 2012 in comparison to 2011. We continue to work towards meeting the goal of a 10% reduction in energy consumption by 2014.

At our head office campus, our 874 Sinclair Road building was updated, including new windows and new roofing with increased insulation helping to improve energy efficiency.

Water savings were realized in part through the implementation of new technology to maximize cooling efficiency for our onsite IT servers. In 2013, we will continue to

explore ways to reduce the energy and water consumption at our corporate offices.

Waste

This past year, a baseline waste diversion rate was established for all of our corporate offices. Information was collected by working with our waste haulers, and through conducting waste audits. In 2012, our waste diversion rate for all corporate offices was 55%. Working towards the goal of a 10% increase in waste diversion by 2014, we plan to continue to focus on reducing waste created through our offices by the expansion of waste diversion programs and employee education.

Smart Commute

In 2012, we partnered with

Smart Commute for the second year to encourage carpooling at our Oakville head office. Since the program was launched in the summer of 2011, we have eliminated 3,598 single occupant vehicle trips, driven 122,831 fewer kilometers, avoided 26,670 kilograms of greenhouse gas emissions and saved our employees $79,268 in fuel costs!