Our Initiatives: Restaurants

Environmental Stewardship at Our Restaurants

Packaging: Designs that Reduce Our Impact

At Tim Hortons, we include environmental considerations in packaging decision-making. Designing better packaging, through material reductions, resizing and reconfiguration for

pallet optimization, increased recycled content, and new material types and sources, can result in significant reductions in the associated adverse environmental impacts.

Recent Packaging Improvements

To illustrate some of our successful improvements, here are a few of the changes that we implemented in 2012.

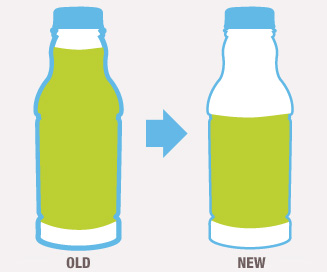

A Better Bottle for Our Iced Tea By working collaboratively with cross-functional internal teams, recyclers of used beverage containers and our vendors,

we improved the recyclability of the bottle by changing the sleeve to a label.

In addition to improving the recyclability of the bottle, making it easier for the plastic to be used for new bottles and products, this initiative resulted in:

- 38% reduction in the weight of the bottle, and

- 98,580 kilograms of reduced packaging material per year.

Reconfiguring the Hot Beverage Cups for Transport

By slightly reducing the total number of cups per case in our small and extra-large and re-evaluating the pallet configuration, we were able to get more cases of

cups per truckload.

This initiative will result in:

- 9,228 fewer pallets shipped, and

- 316 fewer trucks on the road each year.

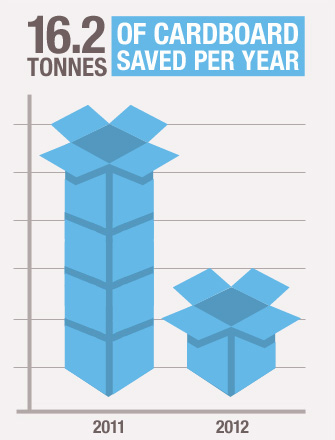

More Garbage Bags per Case

We increased the case size of our garbage bags in order to get more garbage bags to our restaurants using fewer kilograms of packaging material and fewer kilometers travelled.

This initiative will result in:

- over 120,000 fewer cartons,

- 1,400 pallets transported, and

- 16.2 tonnes of cardboard saved per year.

A Lighter Weight Muffin Tray

Working in conjunction with our muffin supplier we were able to reduce the weight of our trays through a modified design.

This initiative resulted in a 5% reduction in material, and will save over 54,431 kilograms of plastic annually.

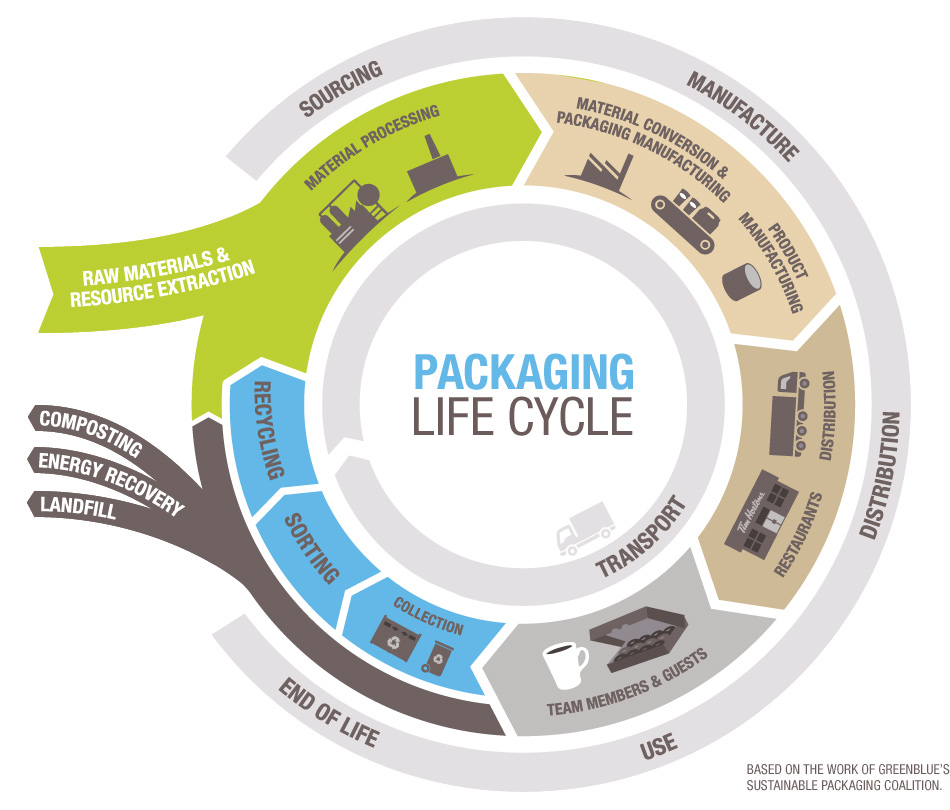

Standardizing the Environmental Evaluation

In 2012, a cross-functional team worked to develop a standardized process for evaluating the environmental impacts of our guest facing packaging.

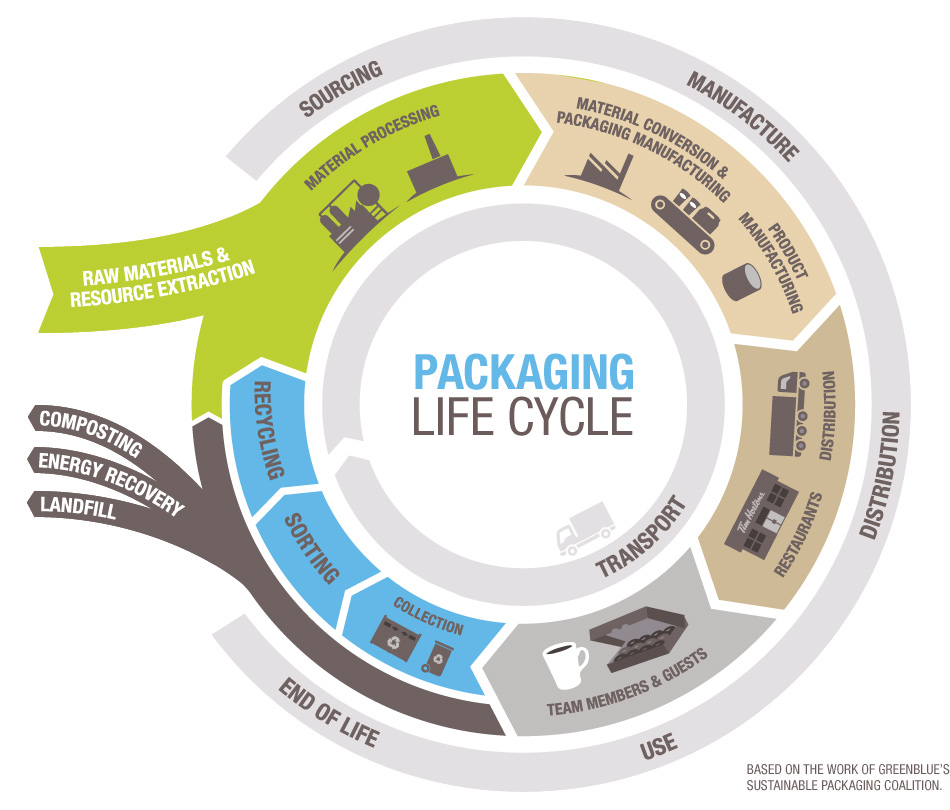

As a first step in this process, we undertook an external assessment of three major packaging types within our operations based on a lifecycle approach. This initial step allowed internal

stakeholders to understand the activities contributing to each packaging type’s environmental impacts and the range of impacts beyond those linked to the waste produced at a package’s end-of-life. These assessments confirmed that how the package is disposed is a relatively small impact over the course of the package’s lifespan and that the key activities were raw materials extraction and conversion of the materials to packaging.

Based on this knowledge, our cross-functional team established a new process for illustrating and better understanding the environmental impacts of packaging. This process uses

a lifecycle approach to assess the environmental impacts associated with materials extraction, production processes, transport distances and end-of-life scenarios of key packaging formats.

With the process for evaluating the environmental impacts underway, we will assess packaging (new and existing) through this new lens in 2013 and continue to balance the

environmental evaluation with product protection and guest safety.

For more details on our packaging see the

Anatomy of Our Cup video.

AT OUR RESTAURANTS: WASTE

As we strive to reduce the waste we create in every part of our business, one of the most important areas of action, particularly for our guests, is tackling the waste generated

at our restaurants. We are working towards this objective by considering the environment in the

design of our packaging

and implementing reduction, reuse and recycling initiatives in our restaurants.

Our Restaurant Waste Profile

Annual waste audits provide insight into the amount of each type of waste that is generated and how we sort our waste. During the audit, all waste generated at a particular restaurant is sorted to determine whether it can be reduced, reused or recycled.

The following chart represents the average proportion of waste (by type of material) generated at a standard Tim Hortons restaurant based on waste audits conducted annually.

Note: This is a representation of total waste generated and does not depict what is diverted through recycling and/or composting.

Waste audits will continue to be completed each year in order to identify trends in waste generation and reduction opportunities in various geographic locations.

We Reduce Waste First

While recycling and composting are great solutions for waste, eliminating the use of single-serve packaging in the first place is even better. We continue to encourage our guests

to use china mugs, plates and bowls when dining in our restaurants and guests also enjoy a 10-cent discount when they bring in their own travel mug.

Waste Diversion Programs

In instances where packaging and other waste cannot be reduced or avoided, we are committed to implementing and increasing access to waste diversion programs. These include recycling

programs for cardboard, beverage containers (bottles and cans), and paper packaging as well as composting programs for coffee grinds, food waste and other organic materials.

Our waste diversion programs vary between restaurants because they are located in different communities that have unique opportunities regarding which items are accepted for recycling.

Additionally, our Restaurant Owners use different waste management service providers, which may also impact the items that may be included in recycling programs. This is why the

multi-stream recycling units developed for Tim Hortons can display different signage for each restaurant’s unique waste diversion programs.

By the end of 2012, 2,057 restaurants had our uniquely designed recycling units. The availability of these units allows for the implementation of plastic and aluminum beverage

container recycling programs as well as the flexibility to expand recycling programs to include paper recycling and composting as services become available in their community.

The chart below identifies the number of programs in each province.

| Province |

Number of Restaurants with

Bottle and Can Recycling |

Number of Restaurants

with Hot Beverage Cup and

Paper Packaging Recycling or Composting2 |

Number of Restaurants

with Organics Diversion3 |

| 172 |

– |

– |

| 189 |

7 |

13 |

| 44 |

– |

1 |

| 100 |

52 |

100 |

| 49 |

38 |

38 |

| 178 |

158 |

178 |

| 749 |

483 |

126 |

| 19 |

19 |

19 |

| 158 |

100 |

4 |

| 49 |

2 |

– |

| 0 |

0 |

0 |

| 0 |

0 |

0 |

| 0 |

0 |

0 |

| Total:1 |

1,707 |

859 |

479 |

1

This chart shows the number of restaurants with our uniquely designed recycling units. The majority of our restaurants not represented are successfully recycling using

stand-alone recycling containers.

2

Hot beverage cup and paper packaging recycling or composting includes our hot beverage cup, soup containers, Timbit and donut boxes, carry-out trays and paper bags.

3

Organics composting units include those located behind the counter and/or in lobby areas.

Hot Beverage Cup and Paper

Packaging Recycling

In 2000, we launched our first hot beverage cup diversion program in Prince Edward Island. Since then, our hot beverage cup and paper packaging recycling and composting programs

have increased every year. By the end of 2012, hot beverage cup and paper packaging diversion programs were offered in more than 850 of our restaurants. As part of our goals

related to restaurant waste, we hope to increase the number of restaurants diverting paper packaging (including our hot beverage cups) by 20% by 2016.

Increasing Access to Hot Beverage Cup Recycling

When we first started looking for end-of-life solutions for our hot beverage cups, no one knew whether the cup could be recycled. Now, through work with waste industry experts and mill trials, we know that our hot beverage cups can be successfully recycled. Presently, the challenge is one of access to recycling programs that accept and process our hot beverage cups, rather than an issue with the composition of the cup itself.

There is no consistent standard as to what must be accepted as part of municipal or commercial programs across Canada or the United States. Essentially, each municipality and

waste management company develops a list of items they deem as “acceptable” for recycling or composting. This varies greatly depending on geographic location,

costs to collect and process material, available processing facilities and access to end markets (purchasers of recycled materials).

These variances are particularly challenging for a company, such as Tim Hortons, that operates in both urban and rural areas with varying levels of service and infrastructure.

That being the case, we remain committed to moving forward with improving access to diversion programs for all of our packaging.

We are working with organizations such as

Stewardship Ontario to collaborate with municipalities to demonstrate that hot beverage

cups can indeed be recycled without compromising or contaminating current recycling programs. Some solutions can be

very low-tech and immediate, while others may involve some investment. The collaborative work with these organizations is improving the recycling community’s knowledge to allow for effective diversion of hot beverage cups.

In 2012, through collaboration with Stewardship Ontario, Emterra, the Region of Halton and Brant County, pilots were undertaken to add hot beverage cups to the Blue Box programs in

these respective areas. All partners expect that the pilots will provide insight into the collection, processing and marketing of hot beverage cups as a normal part of curbside Blue

Box programs.

We also discuss these matters with local, provincial and federal governments in an effort to harmonize material collected for recycling across various sectors and geographies.

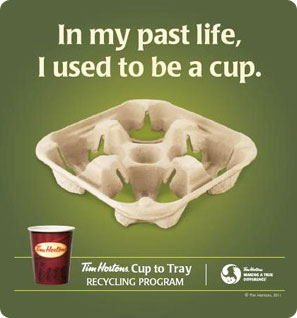

We are also always looking for new ways to incorporate our used hot drink cups in our own packaging products. This closed loop approach will help to provide an end market for our used

paper packaging. In 2011, we implemented our Cup-to-Tray program in Nova Scotia, where hot beverage cups at 156 of our traditional restaurants in the province are collected and

recycled into take-out trays used in our restaurants. At the end of 2012, 249 restaurants across BC, Nova Scotia, New Brunswick and Newfoundland were participating

in the Cup-to-Tray program.

Diversion of Organic Materials

We are also making progress in diverting coffee grinds and food waste. By 2016, we hope to increase the number of restaurants diverting organic material by 20%. In 2012, 479 restaurants across our chain had composting programs in place for coffee grinds and/or food waste. We look for new opportunities to expand these programs where feasible, by identifying new service providers, equipment and processes for restaurant owners and entering into pilot projects to demonstrate the value of diverting these materials.

The Key to Success: Guest Participation

Our progress in waste reduction and diversion is only possible through the participation of our guests. As our guest, you are the key to successful recycling and composting programs.

By putting items in their proper place, you help ensure that items remain out of landfill.

When items are placed in the wrong container, it can compromise our ability to recycle and/or compost your packaging. For example, when recycling hot beverage cups, lids need to be removed

and placed in a separate compartment from our hot beverage cup.

Programs vary by restaurant, so please take a moment to look at the signage before disposing of your packaging.

The success of our waste diversion programs is truly in YOUR hands.

Community Clean-Ups and Litter Awareness

We look for new ways to engage and educate our guests through promotional messages in-restaurant and in the neighbouring communities. We support litter prevention through messaging

on our packaging such as “Put Waste in its Place,” and the majority of our restaurants also post a “Be a Good Neighbour, Don’t Litter” message at the exit of their drive-thrus.

One example of how we look to encourage our guests and communities to participate in our diversion programs and keep our neighbourhoods clean is our support for

Community Clean-Ups and Litter Awareness campaigns.

To help tackle litter in our communities, we have taken a leadership role by supporting local community clean-up initiatives. Throughout the year, our restaurants partner with

municipalities, schools and local community groups to support a variety of community clean-up programs. In 2012, we supported 171 local community clean-ups across Canada

and 3 clean-ups took place in the U.S. This was a 20% overall increase in the number of clean-ups in 2012, when compared to 2011.

In 2012, we also had an increase in the number of restaurants that were participating in our Anti-litter Awareness Program. The Anti-litter Awareness Program ran in restaurants

from April 9th until May 6th and a total of 2,148 restaurants participated. This was an increase of 39 restaurants over the previous year.

Collaboration and Outreach

In an effort to increase the awareness and availability of recycling programs for our packaging, we continue to collaborate with industry peers and the waste management industry.

We continue to be active members of PAC NEXT and the Food Service Packaging Institute’s Paper Recovery Alliance. These groups are committed to improving end-of-life solutions for packaging. In 2012, we also joined the Sustainable Packaging Coalition (SPC) to further engage our peers on meaningful discussion and initiatives concerning packaging. During the spring SPC meeting, we participated in the panel concerning corporate leadership in sustainability.

It is our hope that this further collaboration and sharing our lessons learned will lead to increased availability of curbside recycling programs for hot beverage cups.

Compliance Programs

Funding for Municipal Recycling Programs

Tim Hortons contributes to stewardship programs in Ontario, Quebec and Manitoba that subsidize the cost of municipal

recycling programs.

Fees are paid on packaging considered to be managed by municipal programs, regardless of whether it is actually collected

and managed in municipal recycling programs. This

includes all of our Tim Hortons branded packaging, such as our hot

beverage cups.

We also partnered with other businesses to develop a similar funding program for British Columbia through the creation of Multi-Material British Columbia. As required by regulation, Tim Hortons and other packaging stewards will begin funding the recycling and recovery of packaging and printed paper generated by residents of BC beginning in 2014. The program is also tasked with increasing the recycling rate for the province from 50–57% to 75%.

Deposit-Return Programs

Tim Hortons also participates in deposit-return programs for our branded beverage containers so that fees are paid to the appropriate agencies. We participate in these programs in the following areas: British Columbia, Alberta, Saskatchewan, Quebec, Newfoundland and Labrador, Nova Scotia, New Brunswick, Prince Edward Island, Northwest Territories, Yukon, New York and Maine.

GREEN BUILDING DESIGN

We are continually evaluating new technology, design and construction methods to improve the energy and water efficiency of our buildings and to reduce our overall environmental

footprint. At the same time, our Restaurant Owners benefit by saving money on the utility costs to operate their restaurants. We pilot and test emerging technologies and, where

feasible, introduce them into our standard restaurant designs. For a green building product or technology to succeed it must meet three key criteria:

- Is it cost effective? Up-front costs may sometimes be higher but yield significant payback over time.

- Is it repeatable? New technologies often require other changes to the restaurants that aren’t feasible for us.

- Will it work? Many ideas work well in residential or large commercial developments but don’t meet our needs.

In 2012, we continued to work on reducing operating costs and challenging our suppliers to provide more sustainable green building solutions. A formal Request for Proposal was

initiated to find the most efficient lighting. Tests on energy management systems and whole building commissioning were started as well. Many items to improve the efficiency of the

building and occupancy well-being were tested in 2012 and will be integrated into our 2013 renovations and new restaurant builds.

Reducing Energy and Water Consumption

Each year, we update our standard restaurant designs to include more energy and water efficient initiatives, as well as to enable our designs to meet the constantly changing building codes that apply to our business across Canada and the U.S.

In 2012, we redesigned the interiors of some of our restaurants to include welcoming features like televisions, fireplaces, and more relaxed seating options. Changes to the décor included

new finishes and an open ceiling concept. All these changes bring new opportunities for improvement. With several concept restaurants now in operation, energy comparisons are now underway.

Leadership in Energy and Environmental Design (LEED®)

In 2012, we registered four restaurants for LEED

® Certification and have five additional restaurants in the process of being registered:

- Ancaster, Ontario (registered)

- Nepean, Ontario (registered)

- Toronto, Ontario (registered)

- Syracuse, New York (registered)

- Scarborough, Ontario (in process)

- Surrey, BC (in process)

- Langley, BC (in process)

- Vancouver, BC (in process)

- Syracuse, New York (in process)

We are working towards our goal of registering 30 projects by the end of 2016. We are investigating the USGBC’s (U.S. Green Building Council) Volume Certification Program.

This program was designed for applications just like ours, catering to applicants with multiple, similar submittals.

IMPROVING OUR RESTAURANT EQUIPMENT

At Tim Hortons, our Equipment Purchasing Team is constantly looking for ways to reduce the environmental impact of the equipment used at our restaurants. One of the ways we do this is

through collaborating with our suppliers to explore new technologies that can be scaled up and implemented across our chain of almost 4,300 restaurants in Canada and the U.S. Below are some

examples of initiatives we worked on in 2012 to help reduce the environmental impact of our restaurant equipment.

Our Millwork

We began the process of requiring all of our Canadian millwork suppliers to use only Forest Stewardship Council (FSC) certified wood for millwork done in our Canadian restaurants.

FSC is an independent, non-governmental, not-for-profit organization established to promote the responsible management of the world’s forests. Using FSC certified products tells

us that the forest products we use are from responsibly harvested and verified sources.

All of our millwork suppliers are now FSC certified and using FSC certified products in our restaurants.

LED Lighting

We have been long-time supporters of the use of Light-Emitting Diode (LED) technology in our restaurants. The efficiency of conversion from electric power to light is higher

with LED lights than with incandescent or compact fluorescent alternatives. In fact, LED lights for our outdoor “Tim Hortons” signs in the United States were part of our standard

building design as early as 2000.

Moving forward, we have required only LED lighting in various applications of our restaurants. For example, our new drive-thru menu boards, walk-in freezers and product showcases

are lit by LED lights.

Ice Machines

All of the ice machines used in our restaurants are Energy Star

® certified and can save about 1,200 kWh annually, or an average of $110/year on utility bills.

Rebate Programs

Our Equipment Purchasing Team works with various municipalities to take advantage of energy rebates and water saving initiatives and programs for commercial kitchens and restaurants.

In 2012, we participated in rebate and water savings programs from Enbridge, Union Gas, BC Hydro, and Manitoba Hydro. Further, dishwashers, LED lighting (in-restaurant and signage),

reach in coolers/freezers and ice machines are eligible for rebates through municipalities where we operate.

In addition, various municipalities across the country have participated in Free Spray Head replacement programs, reducing water consumption per site. Manitoba is offering refrigerator/freezer door gasket upgrades, which 50 of our restaurants participated in at the end of 2012. This initiative will reduce loss of energy on the units, thus reducing energy consumption.

Looking Ahead

Improving the environmental footprint of our restaurant equipment is a key area of focus for our Equipment Purchasing group. We will continue to work as a team with our suppliers,

Restaurant Owners and Research Team to ensure that our restaurant equipment remains as safe, cost-effective, reliable, productive and environmentally friendly as possible.

Based on this knowledge, our cross-functional team established a new process for illustrating and better understanding the environmental impacts of packaging. This process uses

a lifecycle approach to assess the environmental impacts associated with materials extraction, production processes, transport distances and end-of-life scenarios of key packaging formats.

Based on this knowledge, our cross-functional team established a new process for illustrating and better understanding the environmental impacts of packaging. This process uses

a lifecycle approach to assess the environmental impacts associated with materials extraction, production processes, transport distances and end-of-life scenarios of key packaging formats.